Technology

Our products feature revolutionary additives and formulations, setting a new benchmark for excellence

Our superlative high-polarity Ester-Enhancing Technology ensures that our top-of-the-line racing, passenger cars, and heavy-duty engine oils deliver unparalleled performance in every essential aspect. The P-9 and P-12 Ester Technology robustly bond selected Group V chemically synthesized ester molecular structures, achieving maximum levels of adherence, film strength, and thermal repulsiveness across all operating environments and temperatures.

Our P-9 and P-12 Ester Technology excels with Group IV Polyalphaolefins base stocks and commonly used Group III severely de-waxing base stocks, and ensuring maximum solubilization with all kinds of additive systems, guaranteeing unrivalled lubricating and performance properties of our FSR GT Racing, FS1, and D1 GOLD engine oil products. This earns them the title of the best choice for ester-based motor oils.

P-9 Technology brings out the maximum effectiveness and advantages of esters.

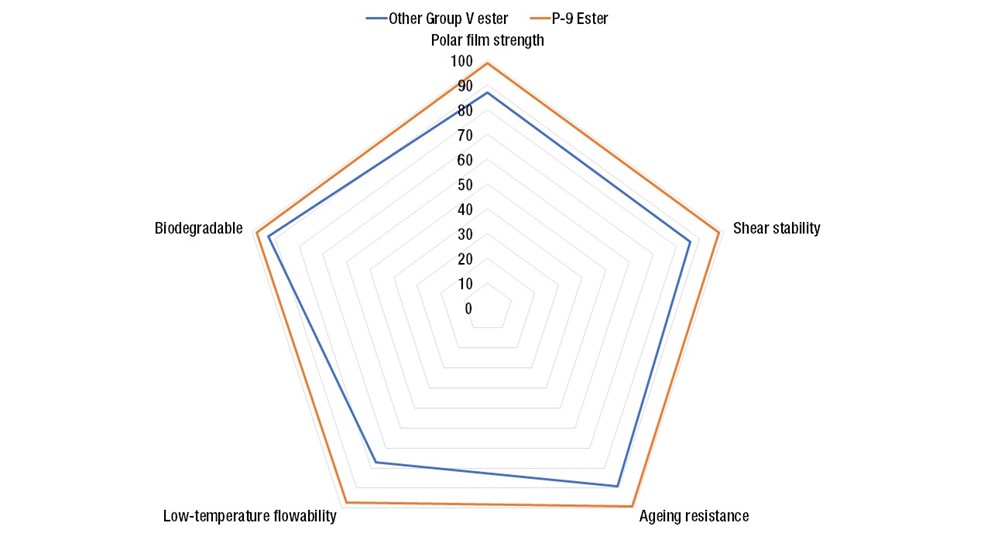

13% higher film strength than commonly used Group V ester base (1)

Polarity refers to the ability of the oil molecules to attract and bond with other molecular structures. P-9 Ester is designed to established unbreakable bond with polar structural and attach to metal robustly. Thence, FS1 motor oils demonstrate better lubrication performance when running at severely high-temperatures and elevated wear protection under extreme load conditions.

14% higher shear stability than commonly used* Group V ester base (2)

Shear stability refers to the property of the oil to resists the action of shear forces and viscosity loss due to related mechanical stressed and destruction. P-9 Ester is designed to help improved viscosity retention (without additional VI improvers) and minimize the possibility of oil polymers dilution (thinning). Thence, FS1 motor oils deliver optimum viscosity-temperature behavior at high and low working temperatures.

11% higher ageing resistance than commonly used* Group V ester base (3)

Ageing resistance refers to the ability to withstand external influences with minimal deterioration of oil and additive qualities. P-9 Ester is designed to enhance the stability of ageing to allow the most stable fluidity performance within the designated drain interval thence, FS1 & FS1 European Makers Formula support long drain interval (especially recommended by European manufacturers in recent years).

7% more hydrolytic stable (biodegradable) than commonly used Group V ester base (4)

Water content (contains bacteria and fungi) is by-product of the esterification process and it can break esters back into alcohol and acid compounds. P-9 Esterification process have been formidable in chemically block the hydrolysis pathway using P-9 branched carboxylic acids and unique fatty acids. Therefore, it maximizes the prevention of biological organism to cleave the ester bond and breaking the compounds into simpler components that can be easily metabolized.

The results of P-9 Esterification were examined using various laboratory methods in ASTM audited laboratory.

(1) Evaluation conduct using Increasing-temperature thermogravimetric (TG) analysis on the ester bond.

(2) Evaluation conduct on shear-stability index (SSI) using advanced ultrasonic shearing test method.

(3) Evaluation conduct in according to ASTM D2893, study on kinematic viscosity fluctuation to determine the rate of degradation.

(4) Evaluation on hydrolysis reaction to identified the rate of hydrolytic degradation, result was acquired on the 731th day.

The dense oil film created by our unique synthesizing work does not allow air and moisture to pass through, preventing rust damage. The naturally antioxidant properties of esters also allow minimal oil degradation to support a better engine cleanliness and extended maintenance life.

The molecular structures of P-9 ESTERs are attracted strongly to one another, so that it requires significantly more energy to vaporise them, giving them a higher flash point than ordinary synthetic base stocks. In return the least oil consumption.

Excellent pumpability in accordance to the MRV test in comparison to ordinary synthetic base stocks, the ester particles spread and penetrate much faster into all engine parts at cold ambient to functionally prevent morning corrosive and wear.

High-polarity ester molecules are combined to form an extremely strong protective film and attached to all moving metal surfaces. They allowed viscosity “stay-in-grade” for much longer at extremely high operating temperatures, fight-off shear and thermal stresses uninterruptedly.

Our products feature revolutionary additives and formulations, setting a new benchmark for excellence

Count on seamless usage of our motor oils, fortified by our meticulous quality assurance processes

Years of endeavor in laboratory, racetracks, and harsh marine environments yield our superb products

Consider us your partner in distribution, offering invaluable support for your growth and successes